This alarm appears if there is a break in Channel 1 (24V) or Channel 2 (0V) of the emergency stop circuit. SRVO-230 or SRVO-231 Chain (1 or 2) abnormal

#Fanuc paint pro code

This code appears when the “deadman” buttons are released, when the protective envelope (fence) of the robot is open, or when one of the emergency stop buttons is pressed. SRVO-162 Deadman/Fence or Panel/External E-stop This alarm appears when the “deadman” buttons are released, or the robot’s fence is open. SRVO-161 Fence open or Deadman switch released

The controller emergency stop button or the external emergency stop has been pressed. This alarm protects the motor and amplifiers against thermal damage. The RMS current calculated by the “servo-drive” exceeds the allowed value. SRVO-062 BZAL alarm (G :x A :x) or SRVO-084 BZAL alarmĮncoder batteries have low voltage or the encoder cable is disconnected. The yellow buttons on the back of the controller have been released while the programming the robot in T1 mode. SRVO-003 or SRVO-234 Deadman switch release The SHIFT key was released while the program was running in T1 or T2 mode. PROG-048 Shift released while running (prog) This alarm indicates that the robot is unable to go to the requested position. The requested position is close to the singularity (parallel J4 and J6). The execution of the macro has been interrupted.

#Fanuc paint pro manual

This code means that one of the robot’s manual movement keys was pressed before the SHIFT key was pressed. The robot’s manual movement key was pressed but the SHIFT key was not pressed. The selected work tool is not the same as the position tool. The number of the work plan is not valid. By correctly identifying and understanding your FANUC robot programming error codes, you can protect your investment and keep it performing at its best for years to come. However, you may occasionally come across programming error codes that you should be aware of to keep your machines operating at peak efficiency.Īn error code may seem like a sign that something is wrong, but really they are alerts that can tell you that something needs to be changed before your robot is damaged. When you purchase a FANUC robot, you can expect everything to work seamlessly and to get quality results from your investment. Window.dataLayer = window.dataLayer || įunction gtag()(window, document,'script',įANUC robots set the standard for quality, reliability, and efficiency. From small shops to large production operations, manufacturers rely on FANUC automation to improve productivity, increase quality, maximize profits and maintain a competitive edge.28 FANUC robot programming error codes (and what they mean) | Blog | DIY Robotics

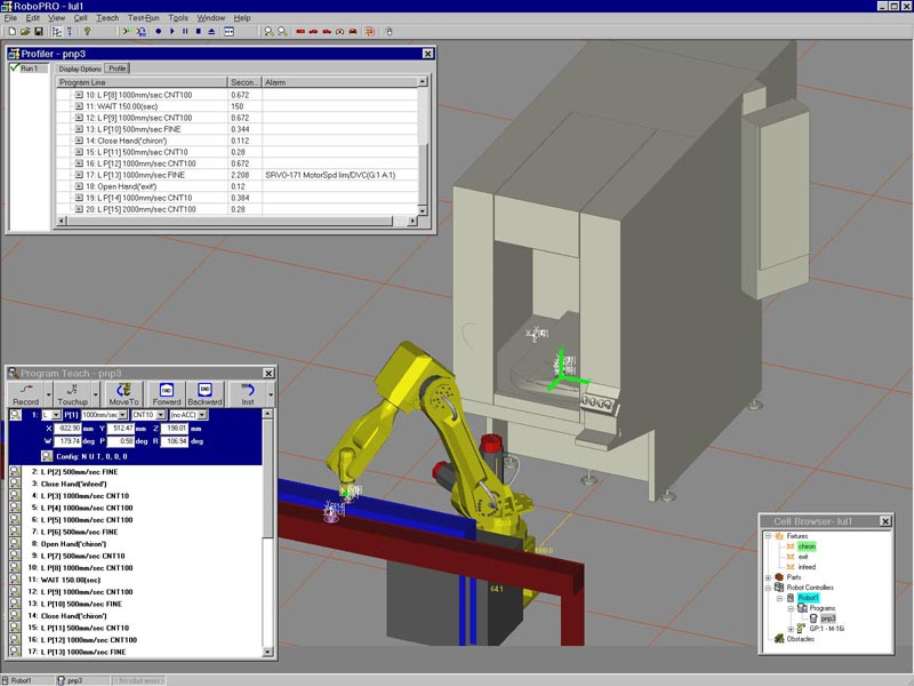

#Fanuc paint pro Offline

Other noteworthy products are the ROBOGUIDE offline simulation suite and Industrial IoT solutions like Zero Down Time (ZDT), which help customers develop, monitor, and manage their automation. Intelligent features such as Force Sensing and integrated iRVision® machine vision provide additional programming flexibility.

#Fanuc paint pro plus

FANUC’s R-30iB Plus robot controller features an intuitive user interface providing easy setup, programming and operation for both novice and advanced users. We offer an extensive range of robot models with payload capabilities from 0.5 - 2,300 kg. FANUC is renowned for innovative, reliable products that come with a Service First commitment that provides lifetime product support. FANUC America is the global leader in robotics, CNCs, and ROBOMACHINEs with over 25 million products installed worldwide.

0 kommentar(er)

0 kommentar(er)